The National Oilwell Varco manual lock Model SLX ram blowout preventer provides a rugged, reliable preventer that is easily serviced in the field. Special features include:

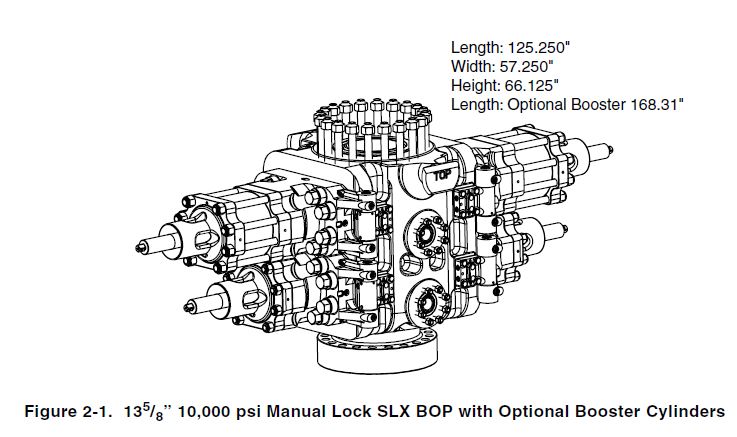

The manual lock SLX BOP is available in single and double models. (Contact World Petroleum Supply Sales for special configurations.) This manual provides the installation, operation, and maintenance procedures for the SLX BOP model with 15.25” manual locking cylinders. See Figure 2-1 on right

These BOPs are designed for drilling and workover service. They are hydraulically operated and can be manually locked by turning handwheels. The standard trim unit is suitable for internal H2S environments. Units can be manufactured for Arctic (to -75° F or -59° C) and full H2S environmental services. Standard units can be retrofitted for full environmental H2S service. Shaffer preventers are manufactured in accordance with the American Petroleum Institute (API) specification 16A (third edition) and the National Association of Corrosion Engineers (NACE) document NACE Standard MR 01 75. Hydraulic pressure of 1,500 psi (103 bar) will close any model SLX ram BOP with its rated wellbore pressure or less. Maximum of 3,000 psi (207 bar) can be used. The specifications and dimensions given are for the 13 5/8” 10,000 psi manual lock SLX. The Shaffer model SLX ram BOP can be supplied with booster cylinders if required. See Figure 2-1 on Page 2-2.

Exposure to the daily hazards of drilling can lead rig crews and service personnel to disregard or overlook hidden hazards. The safety precautions listed below should be observed at all times.

Turn off the system power and bleed all pressure prior to making any repairs or adjustments that do not require system power.

Hydraulic lines carrying fluids at high pressures can inflict potentially fatal injuries if the pressure escapes. Protect hydraulic lines from cutting, scraping, pinching, or other physical damage. Always wear hard hats and safety glasses when working around hydraulic lines. Bleed the pressure from any hydraulic line prior to disconnecting any fittings. Respect the prescribed ASME code minimum bend radius for hydraulic lines. Bending around too short a radius can rupture the line.

Do not weld or operate acetylene-cutting torches near unprotected electrical cable, flexible hose, or hose bundles. Weld spatter can seriously damage the hose or cable. Ensure no slag or spatter enters the hydraulic system.

Many of the BOP components, though apparently similar to commercial hardware, are manufactured to system design specifications. To avoid possible hazardous failures, use only exact replacement parts or assemblies. Contact World Petroleum Supply for details.

View Packing Elements and Seal Kits from World Petroleum Supply.